|

| |

This page is still under construction and new text and pictures will be

forthcoming.

Most of the airplanes that I have built in the last 28 years have been

painted with Dope and/or acrylic lacquer. Film covering has its advantages

but there is nothing any prettier in my opinion than a hand rubbed dope finish. This page will

outline the procedures and materials that I have used in the past along with

methods that other people have used.

The chart below doesn't cover

all of the possibilities of compatibility but is a start. The only sure way

to make sure that your products are compatible is to test them on a scrap

part. One that isn't listed on the

chart is Nitrate and Butyrate dope. Butyrate will go over Nitrate but

Nitrate will not go over Butyrate. I have been told that Nitrate is not

fuel proof but have never tested this.

Film Coverings The major drawback with film coverings (Ultracoat,

Monokote etc.) is the tendency to wrinkle when the wood underneath swells or

shrinks with humidity and the covering to eventually lift at the seams or edges

when exposed to fuel. Goldberg Ultracoat is less prone to this than Monokote in

my opinion although the availability of more colors becoming available have given the builder more

leeway in designing an attractive covering scheme.

The film coverings definitely have an advantage where time is a factor.

They afford a good looking model with minimal effort. Nathan Carter and

Bill Pence come to mind when it comes to a beautiful film covering job.

It is my intention to solicit their articles on film coverings for this web page

in the future.

Sand, Sand And Sand Some More. Probably the one skill that is most lacking in modeling is how

to use sandpaper. The paint job starts with sanding the structure of the

airplane and ends with sanding the clear coat before buffing with compound which

by the way is liquid sandpaper. It is imposable to get a good paint job on a

structure that has gaps in the wood or seams that have not been block sanded

properly. If the structure is tight and smooth less filler is used and a

lighter paint job will result. Wavy trailing edges and rippled sheeting

will stand out when a glossy paint job is applied. If you are

willing to devote some time you will be rewarded with a great looking

airplane. Another thing to remember is the skills to paint a show plane

will not be developed on one or two airplanes but many. Also applying a

light weight painted finish that is shinny takes some practice and skills with

sandpaper.

I prefer to use sanding bars that are the length of the part that is being

sanded such as leading and trailing edges. Square 1" tubes that have

sandpaper of different grits such as 100 and 200 applied to opposing sides work

well.

Once the airframe is sanded and you are happy with the outline now is the

time to knock down all of the sharp edges. Even though the plane is

straight and the seams are tight, the corners of the ribs, stringers and

sheeting around the open rib bays need to be rounded to keep them from cutting

through the covering. If the sharp corners are left around these areas the

sandpaper will inevitably cut through these areas when sanding the paint or

filler coat. I have used 600 to 1000 grit sandpaper for this and they both seem

to work well. The finer the grit the less chance you have of sanding away

too much material. Now is a good time to sand the sheeting with 600 or

1000 grit sandpaper to remove the fuzz. If painting a fiber glass

airplane or part I use 320 grit to remove the gloss of the fiberglass before

priming with automotive lacquer primer. If priming small parts like

cowlings or wheel pants the automotive primers in a spray can work well.

Fillers And Putties Try to keep the airframe tight to keep the

fillers to a minimum. If filling the bare wood and the gap is not to large

microballoon putties work well and are light. These putties are not strong

enough in my opinion for fillets. Auto body acrylic lacquer putties work

well for small imperfections but are heavy. These putties blend to a fine

feather edge easily and dry rapidly. The acrylic lacquer putties from 3M

come in Red Green and Blue colors. The drying times vary from slow to

fast. I have used mostly the blue and green. Since these putties are

a lacquer base they adhere to the dope finish in case you need to fix a ding

when the plane already has paint on it. I have never used the Bondo fillers

since I feel they are too heavy for model airplanes.

I have always applied the fillets after the plane is covered and primed so as

to keep the paint buildup to a minimum. where the fillet is to go keep the

paint buildup thin. I have had trouble in the past

with too much primer and or dope building up on the fillets and causing the

paint over the fillet to bubble or lift. Only one coat of primer or dope filler

is applied to the top of the fillet before painting. For fillets of 1/8

inch or more I use a blend of epoxy and microballoons. Z-Poxy or Smooth

and Easy seem to work well for this purpose. Add enough microballoons to

give the mix a thick consistency that appears to be dry. Apply the

Micro mix with a radiused tool made out of 1/16 plywood. If the micro mix

has to be smoothed slightly you can wet your finger with Isopropyl rubbing alcohol.

Once the fillet is cured it is sanded with 200 to 320 grit wrapped around a

radiused tool to achieve a uniform shape. Sanding the fillet also exposes

the microballoons and allows the paint to get a better grip for adhesion.

Applying The Covering (Silkspan, Japanese Tissue, Sig Koverall,

Polyspan) I have always applied one coat of Sig Nitrate dope unthinned to

the bare wood sanding after each coat with 600. The reason for using Sig

Nitrate is to seal the wood and create a base that the covering will adhere

to. When using polyester coverings it is mandatory for proper adhesion of

the covering unless you are using Sig Stix-it to adhere the covering to the

framework. The first coat of dope on the polyester covering is always

Nitrate followed by Butyrate. Butyrate can be applied over Nitrate but

Nitrate will not go over Butyrate. Another advantage of Nitrate is the

thick glue like characteristics. This comes in handy when trying to seal

the fuzzy edges of Koverall before sanding and blending. Covering an open framework is mandatory for obvious reasons but

what about those sheeted foam wings and wood fuselages? To get a good

finish or a grain free finish covering will have to be applied over the bare

wood to keep the grain from showing through. The type of covering is

dependant on the type and size of the airplane. Sheeted scale planes will

benefit from silkspan covering to keep the grain from showing through. Silkspan

is a good choice for those small R/C planes and comes in three different

weights. K&S silkspan is the most user friendly brand out there since

it sands better than other brands. For further information on covering

with silkspan by Jim Ryan click

here

Large R/C airplanes such as Piper Cubs will benefit from the strength of Sig

Koverall and appear scale due to the desired fabric weave showing through the

paint. Polyspan which is a no woven polyester similar in appearance to

silkspan is stronger than silkspan and is a good choice for those intermediate

sized R/C projects. Polyspan has the advantage of not being affected by

humidity like silkspan and is puncture resistant. The polyester coverings

are applied somewhat taught over the airframe and are shrunk with heat.

Sig Koverall will shrink tight enough to warp a light airframe so caution should

be taken. Polyspan has a more moderate shrink rate.

Japanese Tissue has been used extensively by the free

flight modelers and was not used by R/C modelers until the indoor radio control

models came along. There are products out there that are about the same thickness

as Japanese Tissue but are Polyester. These covering materials have the color

already added to the tissue. I do not have any experience with these

Polyester tissues at this time but have a few small R/C projects that will

require them.

Below are a few articles concerning the Polyspan

covering material. I believe that Polyspan is the ideal covering for mid

size R/C airplanes that are going to be painted. Picture of Steve Starr's

Impact covered with Polyspan and painted with Sig Dope. Steve was able to

achieve a high gloss by wet sanding the clearcoat with 2000 grit sandpaper and

buffing with polishing compound.

POLYSPAN

Excerpts from Larry Davidson's article for Sam Speaks

"I can tell you that this is a great

covering material..."

|

After seeing several ads for Polyspan,

I decided to order a roll and try it out. I also ordered some of the

analine dye that Sal Fruciano (owner of Starline) sells. So far, I only

used the Polyspan on a 1/2a Country Boy free flight and the results are

as follows:

The first thing to know is that this

is a polyester material and impervious to water so don't try to shrink

it with water. The Nitrate dope will shrink if fine and any

wrinkles left can be taken out with a MonoKote iron.

I started on the stab first and

proceeded to follow the brief instructions which came with the product.

He recommends pre-doping the frame outlines in the usual method used for

Japanese tissue or silkspan which is two coats of Nitrate Dope. I

then cut out the Polyspan 1" larger than the outline of the stab

and doped it with Nitrate Dope thinned 50% through the material.

So far everything went well and the material went on easier than

Japanese tissue. Naturally you try to put it on by getting it reasonably

wrinkle-free. Then I cut the material flush with the framework with a NEW

double edge razor blade. So far so good. I then applied the Polyspan on

the top in the same manner and trimmed it leaving the usual 1/8"

for overlapping. Then came the problem. The material does not want to be

rolled over the edges in the usual doping down method. It kept trying to

straighten out the overlap and no matter how hard I tried, it would not

roll over.

I called Sal Fruciano and asked him

for a remedy to the problem and he said that using a Monokote iron to

crease the material should help. Well, he was right and the following

was the method which worked great for me.

Before putting the dope on the edges

to be rolled over, I used the Monokote iron and creased the edge as Sal

suggested. Then I put the Nitrate Dope under the overlap and

rolled it over with my fingers in the usual fashion. It will still try

to come up and by running my fingers around the edges until the dope is almost

dry to the touch, I then took the MonoKote iron set at about 325

degrees and rolled over the edges to stutter when I use the

"M" word. That is because as many know I am a religious silk

and dope man.

The next step was to brush some of the

analine dyed Nitrate Dope on the bottom of the stab. It was

difficult for me to believe that you could get the wrinkles out and make

the covering tight with just putting the dope on. Well I can tell you

that it tightened up great but I did not like the way the color came out

on the bottom or the top. It was streaky and I did use a foam brush.

Then I noticed that the top looked like the Chia-Pet that is advertised

on television as it seemed to sprout fuzz and hair on the top. I

wondered why this did not happen on the bottom and finally realized: IMPORTANT:

There is an inside and outside to the covering. There is one side to the

covering that is more glossy than the other and you MUST

put the glossy side on the outside. On the roll that I used, the glossy

side was on the inside of the roll and when placing a cut piece on the

bench it would try to curl the edges up with the glossy side facing up.

I removed the top covering from the

stab and put another piece on with the glossy side up. As I said before,

I was not satisfied with the orange tinted dope finish which I had

brushed in my usual fashion with a foam brush as it looked streaky and

mottled. The answer was to spray the dyed dope on. This would not be

necessary if you left the material white, which is the only way it is

available. Don Reid, after seeing my Country Boy at the GGG decided to

try Polyspan and then called me to say he had recovered his house

including his wife, Cynthia. Obviously he was impressed with the

Polyspan.

One of the members of our SAM 75

chapter, John Sullivan asked me for a piece of the Polyspan so he could

experiment with the dying process and at our next meeting, he had

produced the following results:

He felt the best way to dye the

material was to use a powdered analine dye. You also may buy the liquid

dye 10 parts of nitrate dope to 1 part of dye, however I found that with

the orange dye, a 20 to 1 ratio worked great.

John says to mix a 2 oz jar of the

powdered dye with one quart of methyl alcohol (methanol) and spray it on

the material before covering the model, otherwise the dye will also

color the rest of the wood of the frame work. You can also use the dye,

both powder and liquid in nitrate thinner and spray this on Polyspan

before covering the plane. If you use the powdered dye, be sure to use

cheese cloth to filter the dyed thinner after mixing it thoroughly.

Because this plane had to be fuel

proof as I use 40% nitro fuel in my Cox TD .049/.051, I continued with

my customary finishing technique of spraying K&B Super Poxy over the

two coats of nitrate dope. The fuselage came out fine, but the wing was

a disaster. The Super Poxy would not fill the pores I the Polyspan on

the bottom. I decided to spray one coat of butyrate dope on the top of

the wing to fuel proof it. I assume that if I applied several more coats

of the nitrate dope to really seal the Polyspan, the Super Poxy would

have worked well.

I can tell you that this is a great

covering material and I expect that on the next plane I use it on will

work well with the techniques I learned on this plane. It really gives

tremendous strength to the framework, probably as much as silk does and

it surely is a great improvement in strength and puncture resistance

over Japanese tissue and silkspan even though it is a little heavier.

POLYSPAN

by Don Typond

(Reprinted from Flying Models, December 1994)

Wouldn't it be nice

if there were a covering material that's strong and stable and just

about puncture-proof, and not any heavier that what's being used now?

|

Polyspan, a modern covering

for traditionalists. Looking very much like the more transparent

silkspan of 30-plus years ago. Polyspan is made of non-woven

polyester fibers randomly intertwined, but with a definite grain

running lengthwise along the sheet. It isn't as stiff as

silkspan or tissue, but rather feels "floppier" and is

soft and silky to the touch. Like silkspan and tissue, Polyspan

is porous, and needs to be filled with dope. It's perhaps best

described as a "paper" made with polyester fibers

instead of wood fibers. But unlike paper, Polyspan is waterproof

and doesn't absorb moisture. Which means it won't sag and change

the airplane's trim on those dewy early morning flights or rainy

day flying sessions.

And it is tough! Trying to

tear it across the grain takes more force than you'll ever put

on a model in normal use. It does tear more easily with the

grain, but is still much stronger than silkspan, and probably

even stronger than silk. Let's put it this way; if you dropped a

quarter on it from two fee up, it'd bounce off. Yes, sharp

objects will puncture it, but the polyester fibers will resist

the puncture growing into a tear.

Polyspan is made in Germany,

and imported by Sal Fruciano. A roll measures 12 feet by 20

inches, and sells for $15.00. Polyspan is available only in

white, but can be colored by mixing dye into clear dope and

spraying it on. (The old method of dyeing in colored water

before covering doesn't work because Polyspan is waterproof.)

Starline by FAI Model Supply sells 2 oz. concentrate dyes in

red, yellow, blue, orange and black, at $5.50 per-ounce bottle,

which will dye a lot of dope at the recommended one-to-ten

ratio. Polyspan can also be painted with opaque dope, of course,

or with other compatible paints once it's been sealed with a few

coats of nitrate dope.

Okay, how heavy is it? I

weighed one-square-foot samples on my balance scale (which I'm

sure is accurate, but even if not produces usable relative

weight comparisons). Polyspan weighs 2.25 grams per square foot,

Japanese tissue ("Esaki" white, from Oldtimer Model

Supply) weighs 1.125 grams per square foot. Thus, Polyspan is

twice the weight of silkspan, and slightly more than twice the

weight of Japanese tissue.

But raw weight doesn't mean

much since these coverings require dope to seal them, and

Polyspan is said to need only two coats of 50-50 thinned nitrate

to fill it. So I made a 12 x 12-inch balsa frame, and doped the

Polyspan to it. Then I thinned Sig nitrate clear dope 50-50 by

volume could result in a more full-bodied material, requiring

fewer coats.) Two coats began to produce a gloss, and filled

most of the grain, but there were still a few small pinholes

that could be seen when I held the panel up to the light. It

took five coats to completely fill all the pinholes, and by then

the surface had become attractively glossy. Obviously, applying

many coats to the entire surface just in order to fill the

pinholes is overkill, and were I covering a glider or

rubber-powered model I would consider two or three coats

sufficient (maybe dabbing a little more on the pinholes),

especially since the dope isn't needed to make the covering

moisture proof.

I then removed the Polyspan

from the frame and replaced it with a sheet of silkspan.

Painting silkspan is like painting a blotter, and the first

couple of costs used a lot of dope as it soaked in. By the time

the silkspan was sealed and the surface no longer fuzzy, I had

applied six coats.

Lastly, I repeated the

procedure with a panel of tissue, which required three coats to

fully seal it.

After allowing 48 hours drying

time, I weighed each panel. The Polyspan weighed 3.6 grams, the

silkspan also weighed 3.6 grams, and the tissue weighed 1.8

grams. In short, Polyspan ends up having the same finished

weight as silkspan, but with much more strength, moisture

resistance, and longevity. Yes, it's twice the weight of

Japanese tissue, which is still my choice for small, light

rubber models, but Polyspan is perfect for larger, heavier

freeflight, control line, and R/C models.

|

|

© STARLINE

BY FAI MODEL SUPPLY

PO BOX 366

SAYRE, PA 18840

PHONE (570) 882-9873

FAX 888-882-9873

Covering and Painting Weights

Here's a table of, purported, covering weights originated by Fritz Bien,

Charles River Radio Controllers, December 1996, with other contributors (August

1995 Flying Models article, Herm Perez, adding covering data, and Radio

Control Soaring Exchange [RCSE] articles):

Covering Weights Chart

| Covering |

Color |

Weight [gm/sq ft] |

Comments |

| Monokote |

Red |

5.8 |

circa 1996 |

| Monokote |

Yellow |

7.5 |

circa 1996 |

| Monokote |

Metallic Platinum |

6.0 |

circa 1996 |

| Monokote |

Red |

7.1 |

circa 1971 |

| Monokote |

Black |

6.0 |

circa 1985 |

| Monokote |

White |

7.3 |

circa 1990 |

| Monokote |

Transparent Red |

5.5 |

circa 1988 |

| Monokote |

Orange Florescent |

9.4 |

circa 1996 |

| Ultracote |

Dark Red |

8.5 |

circa 1996 |

| Ultracote |

Cub Yellow |

6.6 |

0.002 in thick |

| Ultracote Plus |

Pearl Yellow |

8.2 |

0.0022 in thick |

| Ultracote |

Transparent Yellow |

5.0 |

0.0015 in thick |

| Ultracote |

Transparent Yellow (lite) |

3.4 |

0.001 in thick |

| Century 21 Fabric |

White |

10.4 |

Heavy! |

| MicaFilm |

Yellow & Red |

4.0 |

Needs Balsarite |

| MicaFilm |

Preprimed |

3.9 |

|

| MicaFilm |

Transparent White |

2.2 |

Needs Balsarite |

| Sig Koverall |

White |

4.3 |

Needs dope or paint |

| Sig Supercote |

Silver |

4.8 |

|

| Esaki Light Silk |

Clear |

0.97 |

REALLY Hard to put on |

| 5/8 fiberglass/paint |

clear |

3.9 |

Needs filler and color |

| Japanese Tissue |

all colors |

0.65 |

The lightest! |

| Nitrate Dope |

clear |

1.0 |

2 coats/ 50-50 thin |

| Dope, gloss finish |

all colors |

7.0 |

8 clear, 4 color, 1 clear coats |

| Dope, over silk |

all colors |

2.0 |

|

| Polyester Dress Lining |

All colors |

4.2 |

Needs Balsarite & dope |

|

Paint Scheme Design There

are almost as many paint schemes out there as there are airplanes so this is a

very broad subject. There are some rules to follow in designing a good

paint scheme but it comes down to what ever the modeler decides. If every

plane looked alike it would become pretty boring. Can anyone say ARF?

I have included a few of Steve

Buso's paint schemes that he designed for control line aerobatic

models. The schemes shown below will hopefully inspire you do design

your own or borrow some of the things you like and adapt them to your plane.

|

|

This

scheme was designed for Dave Midgley by Steve Buso. The Cardinal airplane

shown here was designed by Windy Urtnowski. So if you are looking for this

airplane look for the Cardinal. Brodak kitted this airplane as a profile.

|

|

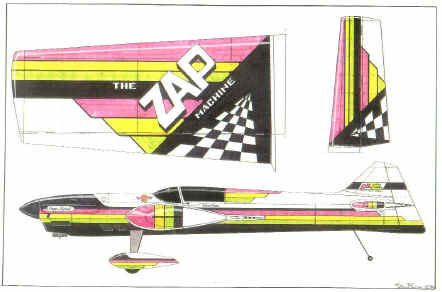

Steve

was the one who designed the ZAP Machine scheme that was extensively used for

the Lanier Stinger airplane. The airplane shown here is Steve's design

that he flew in the Nationals in the late 1980's I believe.

|

|

|

This

was another one of Steve's designs the Jaguar. The scheme was done for

Eric Jensen. |

| This flame job is an eye

catcher. The plane was designed by Jim Casale and the paint scheme was

Steve Buso's |

|

|

The Filler Stage

The

can of Advantage 100 thinner is for cleaning the gun or thinning the Dupont Fill

N Sand to the right viscosity for spraying. The Fill N Sand primer is a fast

filling primer that needs to be thinned 100% to 150% before spraying. The

Advantage 100 thinner is an off brand that was purchased at NAPA Automotive

supplier. The Dupont Fill N Sand is no longer available around the Indianapolis

area due to the phase out of Lacquers but there is a comparable Advantage

product that I have used with the same results.

The Fill N Sand prime works well

over silkspan covering , Sig Koverall or Polyspan. Fill N Sand

can be brushed on the airplane with satisfactory results if the area is not too

large whereas an automotive spray gun will help speed up the process if the

plane is large like the 1/3 Spacewalker . Nitrate dope is the dope of

choice for the first coats against polyester coverings such as Polyspan and

Koverall. The primer can be sanded in about four hours after spraying if the

temperature is around 75 deg F. I sand the first coat of primer with 320

grit paper and subsequent coats with 400 grit. Usually only two coats of

primer are needed. Sanding through certain areas such as rib cap strips is easily fixed by brushing on

the thinned primer. It is important to sand most of the primer away

leaving only the low spots on the first coat. Sometimes it helps to thin the

primer about 150% on the second coat. Thinning the primer over the recommended

amount will cause it to become too powdery with very little hold out.

Primer can be made by mixing one

part dope, one part talc and one part thinner. Fiber Glast in Dayton Ohio

sells talc that is unscented and works well for this purpose. Once the

talc and dope is applied and sanded then a coat of clear will help seal the surface

for better holdout of the subsequent color coats. If you really want to

see flaws in the primer or filler coat spray on a coat of silver and watch those

imperfections pop out. Another technique that is great for finding flaws

on a painted surface is to candle the surface. Candling is when you let

the light bounce off of the surface at a low angle so that it creates a shadow

where there are low or rough spots. It helps if there is only one light so

the others do not wash out the low spots.

|

|

|

Spraying Color And Trim

This has been my

thinner of choice for thinning color and clear Sig dope. It dries relatively

fast but not so fast that the Sig dope blushes. I have had good luck thinning

the Sig dope about 50-50 or 60 dope and 40 thinner depending on the color and

coverage. This has been my

thinner of choice for thinning color and clear Sig dope. It dries relatively

fast but not so fast that the Sig dope blushes. I have had good luck thinning

the Sig dope about 50-50 or 60 dope and 40 thinner depending on the color and

coverage.

Since Du Pont is getting out of the lacquer business

Sig thinner with Randolph retarder added to control drying time and blush

control is an option. Our local NAPA store carries Advantage brand

thinners with varied drying rates that work well. I have always tried to

limit my dope spraying on days with 60% humidity or less. If the humidity

is greater than this then the dope tends to blush. Blush is created when

the paint dries faster than the moisture can escape from the paint. Subsequent

coats of paint applied when the humidity is lower will allow the blush to escape

so have patience and come back later and recoat. It is also beneficial to have

the plane warmer than the ambient air to keep the moisture from condensing on it

when spraying in cooler temperatures. Everyone knows what happens when

they pull a cold drink out of the fridge in the summer (it sweats) and your

plane will do the same. Retarder can be added to the paint but adding too much

retarder will allow the fresh sprayed coats to soften the underlying coats too

much. Cool days in the 50 F to 60 F are good for spraying dope since it

dries slower helping the flow out some.

|

| Masking

Masking an airplane is about 90% of the work in

painting an airplane with more than one color. When someone says

nice paint job what they should be saying is nice masking job. I

have spent hours masking for one color when it only took ten minutes to

spray the color.

When masking out a paint scheme templates made from

see-temp or poster board to guide the tape application come in handy to

assure that the design is symmetrical on each wing.

Some modelers have used masking tape but only after cutting

the edge of the tape with a sharp #11 blade to true it up. I have

always used 3M fine line tape available at automotive stores and have

never had to apply clear dope to seal the edges from paint creeping under

the tape. They don't seal the edges of tape in the automotive paint

world so why should we have to. If you are using trimmed masking

tape you might have to apply clear to the edge of the tape so sticking

with 3M is the way to go in my opinion. When using Friskit film for

a mask I do not seal the edges. |

|

A few of the items that I use while masking off the trim

colors. The Paasche double action air brush took a little getting use to

but with the right tip it works extremely well with dopes.

|

|

The trusty old cheap Buffalo gun is what I use to spray

the primer, color and clear coats. It would help if I had two of

these guns where I could keep one for clear only. If using the gun for

color, primer and clear make sure that you run adequate thinner through it

to keep it clean. Nothing worse than having a red glob of paint come

out of the gun while spraying clear over white. The cylinder behind the

gun is a filter and dryer. The filter dryer can be mounted anywhere

between the compressor tank and the gun but I preferred to mount mine to

the gun. The gun can get a little heavy at times but I am assured of clean

dry air.

|

| Clearcoat And Buff

If you are looking for a show stopping finish then

this is the only way to go. No matter how shinny the paint comes out

of the gun to get that plate glass look you will need to sand the clear

coat and buff with polishing compound. Acrylic Lacquers and airplane

dope shine as well as any two part paints once you have sanded and buffed

them. Two part paints such as acrylic enamels and epoxies are harder

to wet sand and buff to a nice shine but it can be done. I have

sanded and buffed Imron clear coat two days after spraying but dope paint

should be allowed to cure for about two weeks minimum.

3M makes a variety of grits for sanding the color

and clear coats starting with 600 grit and going up to 2000 or above (I

have only used up to 2000 grit). I start with the 600 grit wet until

the top shine is broken and there are still some low spots at the bottom

of the orange peel which show up as shinny. 1000 grit is used next

to get a uniform dullness followed with 1500 and finally 2000. I

have an atomizer that I fill with water and one or two drops of dish

washing liquid such as Dawn to help the paper cut better. Frequently wipe

the water and paint sludge away to see that you are not sanding too

deep. A good thick coat of clear is a must for good sanding and

buffing. I used a little over 1/2 gallon of Sig clear plus thinner

on my 1/3 scale Spacewalker (five quarts total mix).

For buffing compound I have found that Brasso works

well. Brasso seems to have the right viscosity and gives a nice

shine to dope. Brasso can be followed with silver or plastic polish

if you want an even deeper shine. Turtle Wax and McGuire's products

also work well. I have used Turtle wax white polishing compound with

good results but my favorite up until now has been Brasso for the initial

shine followed with Novus polish. There are different brands of silver

polish and they all seem to work well for that final super wet look shine.

|

|

|

Here is a shot of the Spacewalker wing tip after sanding and buffing

with the compounds shown above. The Koverall was extended around the

fiberglass wing tip so everything blends together. The 1/16 inch black

striping tape is a 3M automotive product sold at car shops and was applied

before the clear was sprayed. Although not visible in the picture there is

a little weave pattern under the gloss that will come out more as the

paint cures. Usually a few hot days in the sun is all it takes to get the

weave to come out. I have finished a few parts of airplanes with

fiber glass such as nose sections and the glass will always show through

the primer or filler coats eventually. If you are finishing Sig

Koverall or Stitts Lite covering do not be afraid to fill the weave and

buff since it will inevitable show through anyway. |

|