|

| |

|

This page will cover the application of composites in

model airplanes and ways to utilize carbon fiber and fiberglass in model

airplanes. This page consists of my personal experience with composites

and is by no means definitive. |

|

Common Mistakes

One of the most common mistakes that I have noticed when

a carbon fiber or fiber glass part is designed is the tendency to

fabricate it in the same shape as it's metal or previous counterpart. This

is especially evident in landing gear where the gear is molded to the same

dimensions as its metal counterpart. By making a composite landing gear

flat one can speed up the production process but you loose out on rigidity

and weight savings. When a composite landing gear is constructed with

carbon or glass fabric bagged into a female mold resembling a gutter

all of the fiber that is running the chord of the gear is adding weight

and contributing no rigidity. Since the gear is flat, rigidity is also

compromised. The solution to this problem is to make a carbon fiber gear

that has a teardrop cross section with unidirectional tow running the

length of the gear. By creating a teardrop cross section you increase the

strength and rigidity of the gear while lowering it's weight. When the

gear is molded with a teardrop cross section only one can be made at a

time due to the mold configuration thereby compromising production speed

and simplicity. Carbon cloth or Kevlar can be added to the leg of

the gear where the axle is mounted and where it is mounted to the fuse to

offer splitting resistance.

Ever see that iron on carbon tow? That spider web glue

that melts when heated is only there to keep the fibers oriented and

together while making a preform. A preform is made to fill a closed mold

while the resin is injected or pulled through the mold by vacuum thereby

wetting out the preform. The tow is not made to be ironed on without any

other resin added.

Some thoughts on core materials. The use of core

materials can be very advantageous. When core material is used to double

the thickness of a structure, the relative stiffness increases 7 times.

The strength increases 3.5 times while the weight only increases 1.03

times. When core material quadruples the thickness, the relative stiffness

increases an incredible 37 times, the strength increases 9.2 times, but

the weight only increases a mere 1.06 times.

When glassing the center section of a wing orient the

fiberglass cloth so that both the warp and fill cross over the center

section seam. Warp is the tow that is running lengthwise in the woven

fabric and fill is the tow that runs across the roll of cloth. By

orienting the cloth so that both the warp and fill cross the center

section you are doubling the strength for the same weight. By using a low

viscosity resin for glassing the center section of a wing and extending

the resin a little past the fiber glass will create an edge to sand

against while blending the glass into the wing. |

|

Resin Overview

All epoxy is not created equal. There are literally thousands of

combinations of resins and curing agents available to the fabricator.

The fabricator is not only responsible for making the part but also

creating the material that the part is made from. There are many

resin manufactures that have proven resin and curing agent combinations

available. A good understanding of the cured and uncured properties

of these resins and curing agents will allow the fabricator to make the

right choice when choosing the resin. The choice of resin is

dictated by the parameters that you want the resin to operate in.

Bellcrank and mold.

Polyester is not a structural resin

| Polyester is ok for car repair and non structural

uses (tanks, bins, bathtubs) Lowest cost, highest production

rates (very fast cure rates) Won't work on polystyrene foam (it

softens the foam) Heavy, and hard to obtain proper fiber resin ratios

due to wet out properties. Good secondary bonds are hard to obtain.

Poor bond to Kevlar. Bondo and Featherfill are polyester-based. |

Vinylester is similar to polyester

but has better structural properties than polyester

| Better bond to Kevlar and Carbon fibers than

polyester. Gel time can be extended to 10 hours. Mid-cost,

still less than epoxy. |

Epoxy is the material of choice

for structure

| Cure cycles pace production work. Health

hazards are present. Costly materials. Oven cure varieties

are available to allow large lay-ups. Many varieties to match

specific structural requirements. |

General considerations for all resin

systems

| Health hazards. Workability. Cost.

Chemical resistance (fuel proof). Compatibility with

fibers and core materials. Required service temperature and

moisture environment. Fabricator must understand the materials

they are working with. Clean up issues and hazard waste. |

Resin Matrices

Polyester

| Cures by polymerization (long parallel molecular

chains). Lowest cost resin. Unsuitable for structural

lay-ups, low properties. Limited to low temperature

applications. Insensitive to mix ratio (amount of catalyst

affects cure rate not material strength) High shrinkage

(unstable parts/tools, cloth print through) Polyester part will

not bond to a epoxy part. Contains styrene; therefore cannot

apply over polystyrene foam. |

Vinylester

| Improved version of polyester resin, better

properties, higher cost. Less health risk than epoxy.

properties are between polyester and epoxy. Extended pot life to

allow larger lay-ups |

Epoxy

| Most common structural resin, many different

varieties available. Cures by cross linking (three dimensional

process). Very sensitive to proper mix ratio of resin to

hardener. In the small batches that are used in modeling a

Triple beam gram scale is needed. Highest cost. Room

temperature or oven cure variants available. Absorbs moisture

(hydroscopic). Oven cure variants have higher Tg and Heat

Distortion Temperatures. Will bond to a polyester part.

Multiple health issues. Lowest shrinkage (highest stability).

Excellent adhesive properties (good secondary bonds). Face coats

available for tooling surface finishing. Laminating and tooling

resins available. |

Epoxy Resin Specifications

| Mix Ratio: by weight (most accurate) or by volume.

Typical ranges 100:44 to as low as 100:5 by weight. When mixing small

quantities for model airplanes a triple beam gram scale that measures

in 1/10 of a gram is required. |

| Mixed viscosity, low viscosities required for

laminating resins to ensure proper wet out, high viscosity for tools.

A good viscosity for a hand lay-up is around 500 to 800 centipoise. |

| Pot Life, 100 gram mass; larger masses cure faster,

pot life characteristics limit the maximum laminate thickness possible

per cure cycle. Oven cure resins have extended pot lives, allowing

larger lay-ups to be accomplished. Most resins for a propeller

or similar size part would require only 20 to 25 grams of resin.

Mixing more than you need decreases the pot life and wastes resin. |

| Pot Life for thin film: More representative of time

available to wet out laminate and bag if required. 100 gram mass pot

life is representative of a small batch mix according to the resin

manufactures. Actual pot lives are even less then specified when

thixotropics are used. Thixotropics include micro balloons,

flox, Cab-O-Sil and chopped carbon fibers. |

| Gel Time: Similar to pot life; resin is too

thick to wet out fibers once gelled. |

| Cured Hardness, Shore D: Cured resin can be hardness

tested to assure full cure. When making a part it is important

to save the left over epoxy in order to test the cure. |

| Glass Transition Temperature (Tg): Maximum

temperature at which resin properties diminish appreciably, sometimes

referred to the resins "red line" temperature. When a

cured polymer is heated, vast changes in thermal and mechanical

properties occur. These changes are particularly large near the

glass transition temperature, Tg. Below the Tg, the polymer is

hard and glassy, and above the Tg it has a rubbery state. At

this temperature, tensile strength, hardness, electrical properties

and chemical resistance depreciate rapidly, while tensile elongation

and flexibility increase markedly. Tg usually occurs over a

range of temperature, but for simplicity a single temperature is

selected as Tg. |

| Heat Deflection Temperature (HDT): Temperature at

which the resin begins to soften but still has good structural

properties. The deflection temperature is commonly used as

approximation of Tg. The method for measuring DT has been

standardized by ASTM. The DT is determined on a casting which

has been permanently stressed at (264 psi) by flexural loading and

then heated at a constant rate until the casting deforms a specified

amount. The DT method usually requires a larger sample than Tg

methods. |

| DT's and Tg's provide a measure of crosslink density

of the polymer. Those polymers with higher DT's have higher

crosslink densities, better performance at elevated temperatures and

generally better solvent and chemical resistance. The choice of curing

agent and the cure cycle (degree of cure of the polymer) are the

largest factors affecting DT. You would want a higher Tg resin

on a tuned pipe than on a wheel pant. |

| Notch Sensitivity (Izod Impact): A measure of

the resin's brittleness. A water ski would require a resin that

is a little more flexible than a model airplane propeller blade. A

plasticizer can be added to make the resin tougher and less prone to

fracture. |

| Post Cure: The manufacture's recommended

elevated temperature cure cycle to be used to attain the best material

properties. Post cures either follow a room temperature cure or

an intermediate temperature oven cure for oven cure materials. Free

standing post cures are typically successful if a gradual ramp up in

temperature is used. High-temp assembly fixtures are required if

a free-standing post cure cannot be accomplished. |

| Peak exotherm, Fahrenheit: An indication of a resin's

likelihood to exotherm uncontrollably. The chance of exotherm can be

reduced by limiting mix batches to small quantities, proper disposal

of leftover resin, and knowing your resins properties (testing).

Exotherm is a term used to describe the internal heat generated by the

cross linking of the resin to the hardener. On some resin

hardener combinations a 50 gram mass is great enough to melt a plastic

cup and become hot enough to burn your skin. Larger quantities create

a fire hazard. |

| Resin "Physicals" Include: Density,

Hardness, Viscosity, Elongation, CTE or coefficient of thermal

expansion, Tg, HDT, Pot life, Mix Ratio, Color, Peak Exotherm,

Shrinkage, Izod Impact and others. |

Back to

Top

Materials

Carbon Fibers

| Carbon fibers, Though known since

Thomas Edison's development of the incandescent light in the 1870s,

were not made in large quantities until the late 1960s. At that

time it was found that carbonizing several fibrous materials resulted

in a continuous fiber with relatively low density and high Young's

modulus of elasticity. Modulus of elasticity is a parameter indicating

a material's stiffness. Young must have been the one who came up

with a mathematical way to measure this. High modulus materials

are stiffer than low modulus materials. |

| Fiber Sizing : Sizing are added to fiberglass and carbon fiber to aid

in processing and to allow the resin a better bond to the fiber. Silane

coupling agents are a used as adhesion promoters. While the sizing helps

in the processing of fibers they can hinder wet out of the fabric or tow.

Carbon fiber sizing must be applied to the fiber tow (which may consist of

12,000 filaments of more) to prevent the individual filaments from contact

damage between themselves or with eyelets or guides during weaving or

prepreging. When using tow to manufacture propellers and bellcranks it was

necessary to massage the tow in order to loosen the sizing for better wet

out. The thing to remember when ordering carbon fiber and fiber glass is

that the sizing is compatible with the type of resin you are using. Some

sizings in the fiber glass industry are for polyester only but most

sizings are for both epoxy and polyester resins. One can obtain a discount

on fiberglass with expired sizing when ordering from the mills in

large quantities.

|

| If you have ever handled carbon tow

in the raw state without sizing it is very soft. Fabricators

rely on its tensile strength for the parts rigidity. It is of

great importance to keep the fibers in line with the loads being

applied to it for the best strength properties. Even the crimp

in a carbon tow that allows the tow to be woven into a cloth weakens

the material. This is why unidirectional carbon lay-ups tend to

be the strongest. While talking to Hiroshi Kiyomoto who

fabricated Kaz Minato's carbon wing of his latest Blue Max at last

years Nationals he stated that he used unidirectional carbon in the

wing. One layer was from root to tip and the other was from the

trailing edge to the leading edge. By doing this he could obtain

a stronger lighter wing than would have been possible with a carbon

cloth. Carbon cloth holds excess resin in between the tows if

not compacted with a vacuum bag. Carbon cloth greatly speeds up the

production process though. |

| While carbon fiber is considered a

light weight material in the full size world, it still remains a great

challenge to save weight on a model airplane with this material.

If you are trying to replace 4 to 6 pound per cubic foot balsa with

carbon fiber the results are usually disappointing. The tools to

achieve the proper compaction are out of the hobbyist's range. These

tools are autoclaves and composite ovens. It's still hard to beat a

good piece of 4 1/2 pound balsa for formers, ribs and the like.

Carbon fiber excels on the materials normally constructed from

hardwoods, metal, plastic etc. or high stress areas such as spars and

the like. |

| One of the biggest obstacles to

overcome when designing a part from composite materials is the natural

tendency to copy a part exactly as if it were made from its previous

material. The part should be redesigned to take advantage of the

formability and strengths of the composite material. A composite part

should not be limited to the shape of a metal or plastic part. |

| There are three types of carbon fiber, Rayon,

Polyacrylonitrile (PAN) and Pitch. |

| Rayon precursors, which are derived from cellulosic

materials, were one of the earliest precursors used to make carbon

fibers. The processing disadvantage was a high weight loss, or

low conversion yield to carbon fiber. Typically only 25% of the

initial fiber mass remains after carbonization, which means that

carbon fiber made from these materials is comparatively more expensive

than carbon fibers made from other materials. |

| Polyacrylonitrile (PAN) precursors are the basis for

the majority of carbon fibers commercially available today. They

provide a carbon fiber conversion yield that is 50 to 55%. These

precursors can be thermally rearranged before thermal decomposition,

which allows them to be oxidized and stabilized before the carbon

fiber conversion process, while maintaining the same filamentary

configuration. The chemical composition of PAN precursors

defines the thermal characteristics that the material displays

throughout the oxidation/stabilization portion of the conversion

process. These thermal characteristics influence the processing

sequences that are used to convert PAN precursors to carbon fiber.

Carbon fiber based on a PAN precursor generally has a higher tensile

strength than a fiber based on any other precursor. This is due

to a lack of surface defects, which act as stress concentrators and,

hence, reduce tensile strength. Carbon propellers and bellcranks that

are made by Winship Models utilize PAN based carbon fiber. |

| Pitch precursors based on petroleum asphalt, coal

tar, and polyvinyl chloride can also be used to produce carbon fiber.

Pitches are relatively low in cost and high in carbon yield.

Their most significant drawback is nonuniformity from batch to batch. |

Glass Fibers

| There are literally thousands of fiber glass

fabrics and tows available to the fabricator. For modeling use the

varieties of fabrics under 2 ounces per square yard are the most

common. |

| E- Glass is the most common (and least expensive)

grade of glass fiber. |

| S -Glass is a special grade of glass that is much

stiffer than E-glass and somewhat stronger. |

| The use of fiber glass on a stunt ship is usually

limited to the center section of a foam wing or around the nose

section, either on the outside or for reinforcement around the nose

formers. If using fiber glass to strengthen the center section

of a foam wing keep the glass fibers running at a 45 degree angle to

the center wing joint. This will allow both the warp and the

fill fibers of the cloth to span the wing joint giving double the

strength with no weight penalty. The warp direction is the

direction of the long fibers as the cloth is pulled off of the roll.

The fill fibers are the fibers that run side to side as the cloth is

pulled off of the roll. |

| Almost all glass cloth has sizing applied to it to

aid in resin wet out and adhesion. Some sizings are for polyester

resins and some are for epoxy resins. If the glass cloth or

tow has the wrong sizing for the type of resin used, then the bond

will be weak between the resin and cloth or tow. While this

might not be of great concern on a pair of wheel pants it might

prove to a problem if a speed prop was constructed without the

proper sizing applied to the tow. Usually a fiber glass that

is not properly wet out will have silver of white streaks or spots

in the laminate. |

|

I

decided to make a carbon fiber landing gear for the Midwest Extra 300 to

save a little weight. The carbon fiber landing gear should cut the gear

weight in half over the aluminum component. I

decided to make a carbon fiber landing gear for the Midwest Extra 300 to

save a little weight. The carbon fiber landing gear should cut the gear

weight in half over the aluminum component.

I am using the original gear for the mold. This gear is

a one off so if more than one gear was to be made a matching face mold

would be constructed. The landing gear is mounted to foam blocks for easy

layup. Along the edge of the aluminum there is a balsa dam that is

1/4" above the gear. The height of the balsa edge above the gear will

determine the thickness of the gear. This balsa edge will hold the

carbon fiber on top of the gear while the layup is in progress also. I

will attempt to sand in some teardrop shape to make the gear more

aerodynamic after demolding. Clear packing tape was placed over the

predrilled holes to keep the resin and carbon from running through them. A

Freekote 700 mold release was also used to assure the carbon gear would

release from the aluminum gear. |

|

The

carbon tow has been cut to length and is now waiting for the resin. I am

not sure how many filaments there are since it is not important due to the

fact that every gear will require a different amount of carbon fiber. I

guessed on the amount by placing the carbon tow in the mold to see how

much it would take to fill it. I guessed pretty close since didn't

need to cut additional carbon. The tow was cut a few inches oversize and

was trimmed where it hangs over the end of the gear. The carbon tow

trimming was them placed in the center of the gear The

carbon tow has been cut to length and is now waiting for the resin. I am

not sure how many filaments there are since it is not important due to the

fact that every gear will require a different amount of carbon fiber. I

guessed on the amount by placing the carbon tow in the mold to see how

much it would take to fill it. I guessed pretty close since didn't

need to cut additional carbon. The tow was cut a few inches oversize and

was trimmed where it hangs over the end of the gear. The carbon tow

trimming was them placed in the center of the gear

|

The

carbon tow was wet out on wax paper before placing in the mold. With this

much tow and resin it is a good idea to work fairly fast since the pot

life of the resin is dependant not only on room temperature but the mass

of resin. If the resin is spread out onto the tow you will avoid an

exotherm and increase the working time. The mold was filled to the top or

a little over and will be sanded down to the proper thickness after

curing. The balsa sides will be sanded off after the gear is sanded or

ground down to the height of the balsa. A mid temperature resin was used

that has a heat deflection temperature of 260 deg. F. after post cure. A

high temp or mid temp resin is mandatory for a landing gear in my opinion

since the heat radiating off of blacktop in the summer can reach as high

as 120 deg F. in Indiana. The high temp resins also have greater

structural properties. There are many landing gears that are constructed

by laminating layers of carbon cloth over or in a mold but the carbon

fiber that is running chord wise in the mold is not providing any rigidity

and adding unnecessary weight. If you desire greater strength at the

wheel/axle attachment point you can bond on a piece of carbon fiber woven

plate for splitting resistance. Unidirectional carbon fiber tow is the

strongest and lightest way to make a landing gear and since the original

landing gear can be used as the mold it makes it affordable for the person

who would like a starter carbon fiber project. If for some reason you

still want to use the original landing gear you will be able to after removing

the carbon part provided you do not forget the mold release. The

carbon tow was wet out on wax paper before placing in the mold. With this

much tow and resin it is a good idea to work fairly fast since the pot

life of the resin is dependant not only on room temperature but the mass

of resin. If the resin is spread out onto the tow you will avoid an

exotherm and increase the working time. The mold was filled to the top or

a little over and will be sanded down to the proper thickness after

curing. The balsa sides will be sanded off after the gear is sanded or

ground down to the height of the balsa. A mid temperature resin was used

that has a heat deflection temperature of 260 deg. F. after post cure. A

high temp or mid temp resin is mandatory for a landing gear in my opinion

since the heat radiating off of blacktop in the summer can reach as high

as 120 deg F. in Indiana. The high temp resins also have greater

structural properties. There are many landing gears that are constructed

by laminating layers of carbon cloth over or in a mold but the carbon

fiber that is running chord wise in the mold is not providing any rigidity

and adding unnecessary weight. If you desire greater strength at the

wheel/axle attachment point you can bond on a piece of carbon fiber woven

plate for splitting resistance. Unidirectional carbon fiber tow is the

strongest and lightest way to make a landing gear and since the original

landing gear can be used as the mold it makes it affordable for the person

who would like a starter carbon fiber project. If for some reason you

still want to use the original landing gear you will be able to after removing

the carbon part provided you do not forget the mold release.

Also in the pipeline

is a plug tutorial for a pattern plane.

|

The

carbon gear has finally been released from the aluminum landing gear. Some

of the balsa side structure is still stuck to the aluminum gear but can be

removed by sanding. The

carbon gear has finally been released from the aluminum landing gear. Some

of the balsa side structure is still stuck to the aluminum gear but can be

removed by sanding.

The carbon fiber gear in the picture has been sanded to

a teardrop shape and is constructed entirely from carbon tow. I feel that

a secondary bond of some carbon fiber woven plates at the axle attachment

would be beneficial.

The aluminum landing gear weighs 347g or 12.23 ounces

and the carbon gear weighs 229g or 8.07 ounces for a total weight savings

of 4.16 ounces. The carbon fiber gear at this weight is stiffer than the

aluminum gear and could be made lighter. Since the carbon gear was formed

over the aluminum gear it is slightly taller and wider which I feel is beneficial.

If these composite landing gear were going to be mass produced a matched

mold would have to be constructed to form the cross section of the

gear.

Since I was only going to make one of these landing

gears I used the TLAR (That Looks About Right) Engineering process. After

making numerous parts from carbon tow I had a good idea of the amount of

tow it would take to fill the mold and was able to pre cut the right

amount. If making these landing gears from a matched mold one would need

to keep track of the amount of resin and tow in order to completely fill

the mold. There are production processes available such as VARTM (Vacuum

Assisted Resin Transfer Molding) that would be suitable to producing parts

with this geometry economically. VARTM processes will be covered in

the future although the process isn't cost effective for only one or two

parts.

Thumbnail of the bottom of the Extra 300 carbon fiber landing gear.

Thumbnail of the bottom of the Extra 300 carbon fiber landing gear.

Thumbnail of a carbon fiber control line landing gear mold.

The mold is a matched die type mold and is the type of mold used when you

want to produce a carbon gear that has a streamlined cross section.

Thumbnail of a carbon fiber control line landing gear mold.

The mold is a matched die type mold and is the type of mold used when you

want to produce a carbon gear that has a streamlined cross section.

|

When

I started to mount the kill switch on the Spacewalker I realized that I

needed a right angle bracket to mount the switch. The bracket material was

fabricated from six layers of carbon cloth with four layers of glass

acting as a core. Since the bracket wasn't going to carry a load the fiber

orientation wasn't critical. The bracket could have been made of wood but

the light weight and compact nature of the carbon fiber bracket was

appealing. When

I started to mount the kill switch on the Spacewalker I realized that I

needed a right angle bracket to mount the switch. The bracket material was

fabricated from six layers of carbon cloth with four layers of glass

acting as a core. Since the bracket wasn't going to carry a load the fiber

orientation wasn't critical. The bracket could have been made of wood but

the light weight and compact nature of the carbon fiber bracket was

appealing.

The picture shows the aluminum angle that was used as a

mold. I sanded the aluminum to remove the dirt and lightly polished the

surface before applying the Freekote mold release. The laminate in the

picture has been trimmed and the actual switch mount has been cut away

from the part shown. Since making these brackets are relativity easy I

made a piece large enough to cut multiple brackets from. After the part

was laid up an oven cure of 150 degrees F for four hours the part was

demolded and trimmed. A 250 degree F resin was used but since the part

wasn't going to see that high of a temperature a 150 degree F was

adequate. C clamps provided the pressure to debulk the laminate. |

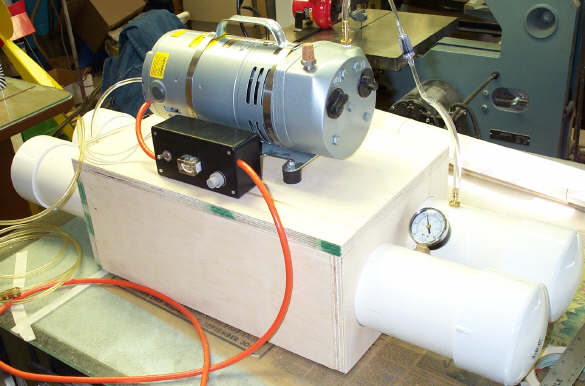

Pictured

here is a vacuum pump sold by Aerospace Composites. The pump will pull

about 18Hg. This pump is an excellent vacuum source for bagging balsa to

foam since the vacuum can be adjusted. When bagging expanded bead

polystyrene you will need to stay under 7Hg to keep from crushing or

distorting the core. The other advantage of this pump is the vacuum Pictured

here is a vacuum pump sold by Aerospace Composites. The pump will pull

about 18Hg. This pump is an excellent vacuum source for bagging balsa to

foam since the vacuum can be adjusted. When bagging expanded bead

polystyrene you will need to stay under 7Hg to keep from crushing or

distorting the core. The other advantage of this pump is the vacuum |

THE

BIG SUCKER THE

BIG SUCKER

This is a composite de-bulking vacuum system that was

built similar to the one shown above except that it is an industrial

version. The Gast pump is rated a 1/3 hp and will pull 28Hg. This

composite vacuum pump is well suited for vacuum bag mlding. The two PVC

schedule 40 pipes provide the vacuum tanks and are inserted into a wooden

box that acts as a motor mount and tank holder for the Gast pump which

sits on four Lord Mounts. The black project box was purchased from Radio

Shack to hold the relay, switch and fuse. The vacuum switch, relay, vacuum

gauge, check valve and miscellaneous fittings were purchased form

Aerospace Composite Products. George Spar sells a new vacuum switch that

is adjustable over the full range of vacuum from 5Hg to 28Hg. The vacuum

switch and 10 amp relay are a critical components for this 1/3 horse

setup. The switch purchased from Aerospace Composites provides a

smaller amount of deadband than other switches that I have tried and is

highly recommended. To mount the vacuum switch, gauge and fittings, the

PVC pipe was drilled and tapped with NPT taps to match the fittings while

a liberal amount of RTV silicone seals the threads. A special thanks

to Steve Ragsdale for his input and help on this pump (he is and

electrician by trade). To view the schematic of this pump click

here. The schematic shows relief holes between the pump and check

valve which are not required on the Gast Rotary Vane Pump since the vacuum

isn't present in this section of hose when the pump isn't running. The

capacity of this pump will debulk large composite lay-ups. Future projects

for this pump are carbon honeycomb laminates for fuselages and oven cured

composite lay-ups. |

|